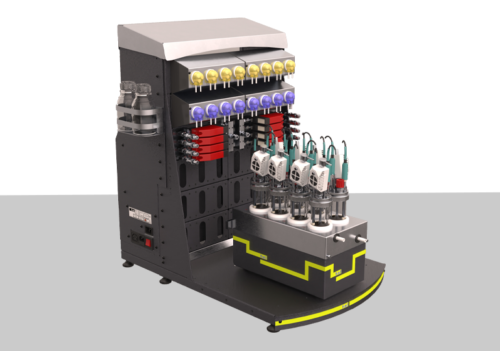

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of critical parameters for aerobic fermentations. The parallel bioprocess capabilities of BioXplorer 400XL, combined with the customizable configuration of the bioreactor lid, unlocks the possibility of choosing what parameters to measure in real-time. Combined with the WinISO, the BioXplorer 400XL is able to respond to the change happening in the bioprocess, allowing for complete automatization of the fermentation.

Overview

Enhanced Bioreactor System

The BioXplorer 400XL has eight bioreactors, each optimized for aerobic fermentation and each allowing 120 mL – 400 mL working volume. These bioreactors can be equipped with a wide variety of probes and sensors, and the system offers multiple gas and liquid feed configurations. The ability to precisely control and monitor up to eight bioprocesses in parallel greatly accelerates screening and optimization studies, leading to more profound process knowledge and faster scale-up.

Flexibility and control

BioXplorer 400XL combines increased larger volumes with the replication and parallelization capabilities of having eight independent reactors controlled by WinISO. This software monitors the parameters of interest in the bioreactor and, at the same time, permits stringent control over them, always maintaining ideal conditions within the reactor. Combined with the ability to customize and the flexibility and variety of liquid and gas pumps and agitation, it results in great tools to characterize and optimize bioprocesses.

Downloads

The following are a list of available downloads.