Batteries with superior attributes

How can we develop batteries with superior attributes?

Calorimetry is a fundamental tool to help build better batteries, including thermally stable batteries, higher energy density, shorter charging times, and longer operational times. In the previous section, we described how different components of a battery are susceptible to failures due to thermal hazard. However, a battery is much more than its basic components or sub-components, and the interaction between them can amplify problems such as thermal runaways, but also help to mitigate their consequences.

Understanding Thermal Behaviour

The electrolyte and cathode in Lithium-ion batteries are the most susceptible parts to damage due to thermal hazards. We can use calorimetry to predict the temperatures at which thermal runaways might happen, evidenced by sudden temperature increases. Processes such as charge/discharge can increase the cell temperature and, as a result, trigger decomposition reactions. The accumulation of energy from the decomposition of the electrolyte can increase the temperature, initiating the decomposition temperature of the cathode. The result of such decomposition is oxygen, which, reacting to the flammable gases accumulated in the battery, can result in fire and explosions.

Additionally, when developing cells, extra elements can be put in place to prevent thermal runaways, e.g., separators. Separators are usually composed of polymers with pores through the structure, allowing ions to transfer. Separators are designed to close those pores at high temperatures, stopping the chemical reaction. However, separators can also fail and, at high temperatures, may shrink, therefore allowing the ionic movement, resulting in a short-circuit. Calorimetry can help to understand how much energy can be released from the decomposition reactions, what temperature is needed to initiate the secondary runaway reaction and the consequences of such a process. The result of this analysis will determine the safe values at which the battery can operate.

Designing Thermal Management Systems

Calorimetry data can guide in the design of thermal management systems for batteries. Elements such as heat sinks, cooling fans, and other heat dissipation strategies are fundamental for maintaining optimal operating temperatures, enhancing performance, extending lifespans, and preventing hazardous scenarios.

Solid-electrolyte Interface (SEI)

The SEI plays a vital role in the safety of Lithium-ion batteries, performance, and operation. The SEI is a thin layer that forms on the surface of the anode during the initial charging cycles of the battery. It is the result of the interaction between the electrolyte and the anode, and it is composed of lithium salts dissolved in organic solvents.

The SEI acts as a physical barrier between the anode and the electrolyte, insulating yet ionically conductive. As it blocks further physical contact between the electrolyte and the anode, it prevents further degradation of the latter, allowing lithium movement. However, over long periods of time and successive charge/discharge cycles, its capacity can fade, resulting in the cells losing its capabilities to hold charge. Moreover, it can increase internal resistance, leading to less efficient charging and discharging and an increase in temperature.

Accelerated aging testing

A battery’s performance decreases over time due to a number of processes, e.g., formation and growth of SEI, progressive degradation of the electrolyte, partial dissolution of the electrodes in the electrolyte, and increased internal resistance. Understanding these processes is fundamental in predicting the lifespan of the battery, but also what are the consequences of operating old batteries. Batteries are exposed to harsh conditions when using accelerated aging tests, simulating long-term usage in shorter timeframes. The thermal response of the battery can provide insight into how its performance and safety attributes change.

Battery failure testing

The formation of low-resistance paths for electric current between the electrodes can result in short-circuits, leading to rapid battery discharge, overheating, and potential fires. At a cell level, this process can occur in a number of scenarios, like a breach in the separator or the formation of lithium dendrites. These occur when batteries are charged too rapidly or at low temperatures. The lithium ions can deposit, forming spikey structures that can grow through the separation, creating a conductive path between the anode and the cathode. Destructive testing allows for the irreversible physical damage of the cell, such as perforation, simulating these processes.

Solutions

Superior attributes could refer to either better performing batteries at safer conditions or the capacity of batteries to withstand harsher conditions.

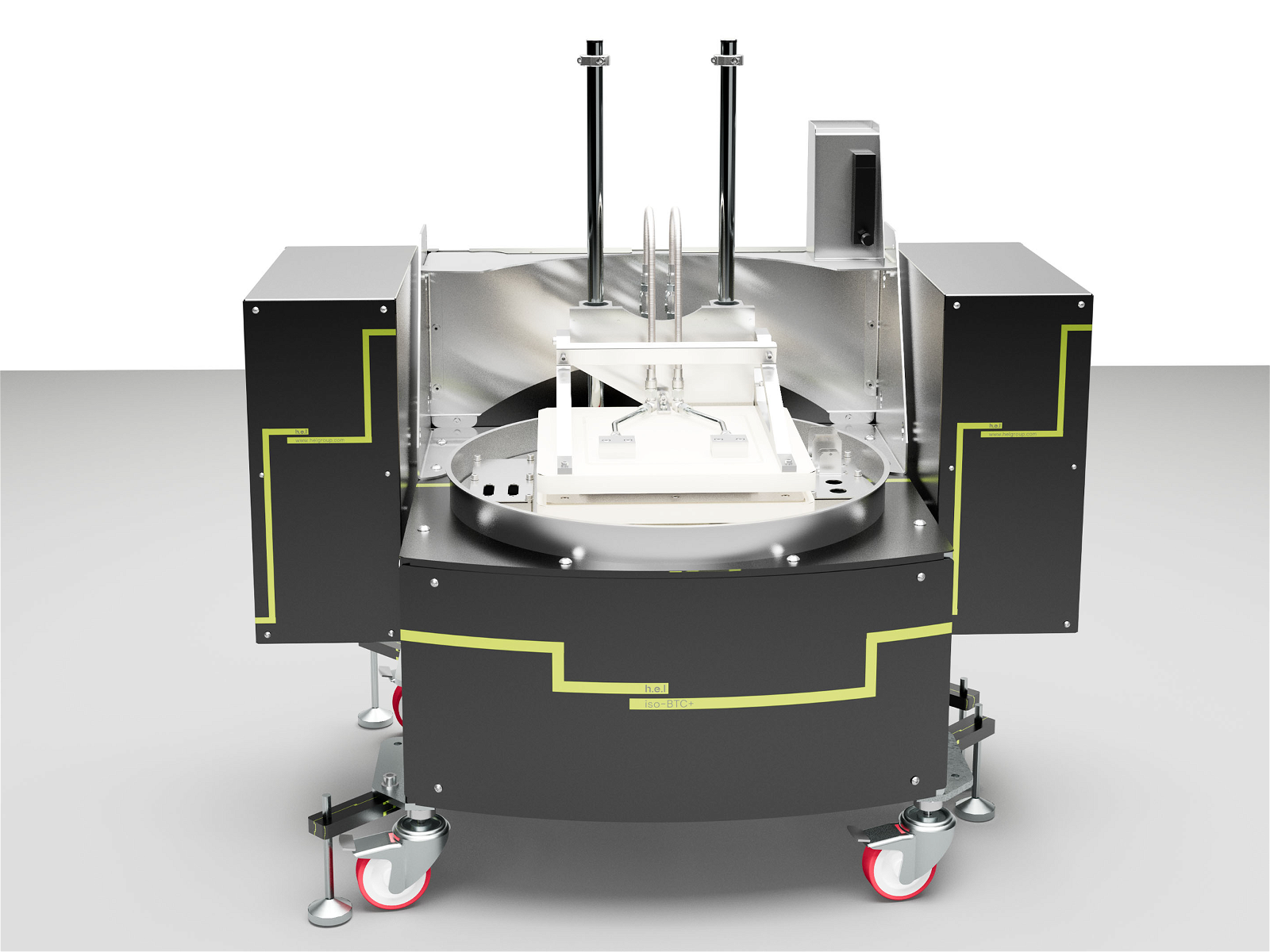

There are some critical points when developing new batteries: larger amounts of energy storage, charge stability overtime, and efficient discharge processes H.E.L’s iso-BTC is an isothermal calorimeter designed to characterize battery cells under normal and extended use conditions. The iso-BTC supports the integration of a charge/discharge unit, allowing for automated, repeated cycling of the battery cells while recording both electrical performance and heat evolved.

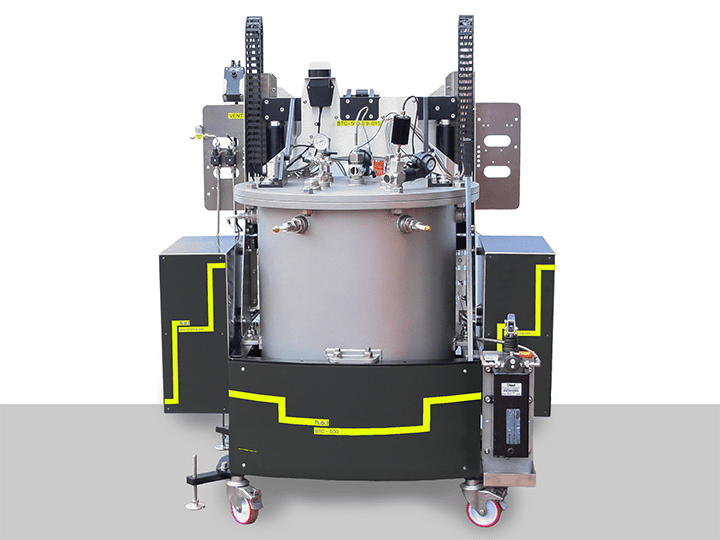

The BTC-130 and BTC-500 are powerful tools to test the behavior of the battery outside of its safe limits. Both BTC systems fully integrate with charge-discharge units to support electrical stress tests, including external short-circuits. Using adiabatic calorimetry, BTC-130 and BTC-500 can help assess the battery’s thermal stability and characterize thermal events. Furthermore, BTC-500 can be equipped with a range of puncture tools and a camera to characterize physical damage events.

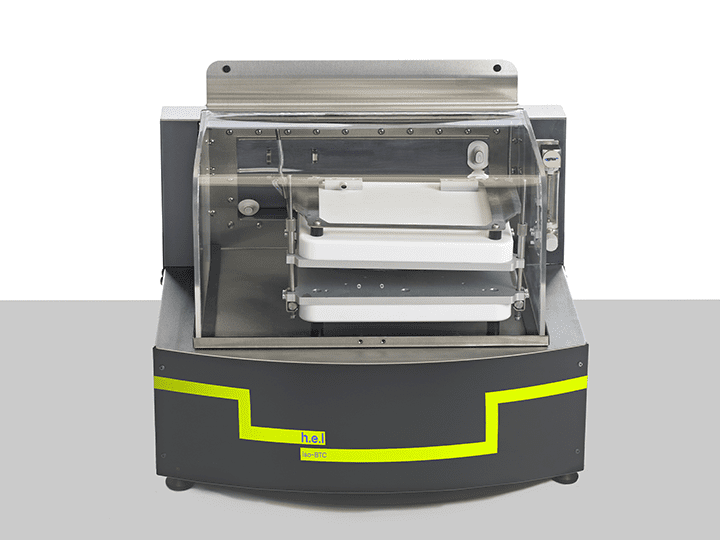

iso-BTC | Bench-top, battery performance testing, isothermal calorimeter

The iso-BTC (Battery Testing Calorimeter) is an isothermal calorimeter designed for the ch...

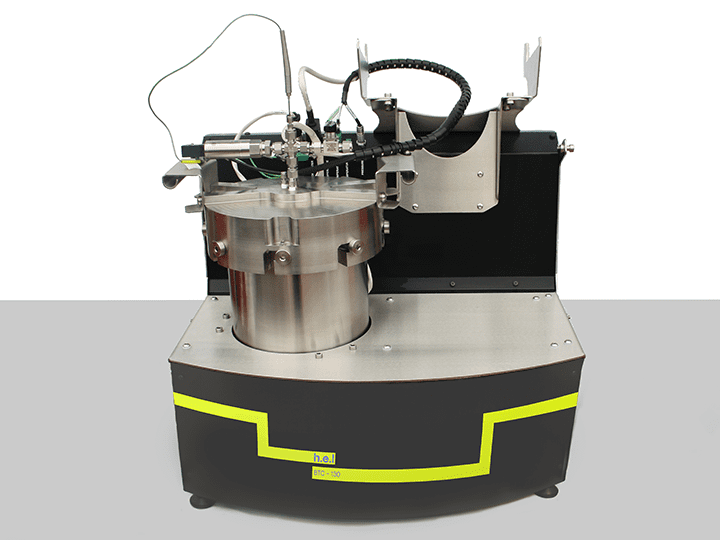

BTC-130 | Bench-Top, Battery Safety Testing, Adiabatic Calorimeter

The BTC-130 (Battery Testing Calorimeter) is a bench-scale adiabatic calorimeter designed ...

BTC-500 | Large-scale, battery testing, adiabatic calorimeter

The BTC-500 (Battery Testing Calorimeter) is a floor-standing adiabatic calorimeter for th...

iso-BTC+ | Floor standing, battery performance testing, isothermal calorimeter

Faster product development, testing, and launch through scientifically robust data: R...