Screening

What processes can be screened using bioreactors?

Gut microbiome and its responses

The microbiome can be defined as the collection of all microorganisms inhabiting a particular ecosystem. In the case of humans, whose bodies are made from trillions of cells, the ratio between human cells and microbial cells is approximately 1:1. The gastrointestinal system contains the majority of microorganisms that live in association with humans. Health benefits and diseases have been tracked to the gut microbiome, which is involved in processes as diverse as digestive disorders and neurological diseases.

Understanding this microbial ecosystem has been deemed a priority in the last few years, with the creation of networks such as the Human Microbiome Project, or INFOGEST. This type of entity aims to promote research in this field and harmonize the techniques used to do so so results are comparable between studies. Characterization of the microbial community and its responses is not an easy task. From cultivation studies to current metagenomic approaches, knowledge has been accrued in the last few years. Studies on what a healthy and “normal” gut microbiome is have been extensively published, as well as variations in this normality and its potential consequences.

However, bioreactors can be very powerful tools for understanding how the gut microbiome reacts to different factors. INFOGEST, on its recommendations, has produce a list of different simulated fluids (such as salivary, gastric, and intestinal). The strict control and automation of bioreactors enable thorough mixing of its contents. The use of tubing allows for the delivery of the simulated fluids in a staggered fashion, mimicking the digestive process. Additionally, interconnection between reactors in parallel systems can help to pump the simulated bolus, replicating the transposition between the different chambers of the gastrointestinal tract. Approaches like this help to understand how food can be digested over time, or how the microbiome can respond to different diets.

Syngas fermentation

Syngas (synthesis gas) is a mixture of gases, predominantly carbon monoxide (CO) and hydrogen (H2) and other minor gases, such as CO2, methane, and hydrogen, derived from the gasification of carbonaceous fuels and biomass. It can be used as a clean alternative to fossil fuels for the production of added-value products and biofuels.

The transformation process from syngas to the final product is usually carried out by microorganisms. Autotrophic organisms have the ability to generate their own organic matter using inorganic carbon such as CO2, CH4, or CO. Whereas photosynthesis (using light as energy source) is the most known type of autotrophy, chemolithotrophy (using inorganic chemical reactions to produce the energy needed for the process) poses a very interesting alternative with application in syngas fermentations. The oxidation of reduced molecules (such as H2 – present in syngas-, sulfur, nitrogen, or iron) can power the cells that fix the inorganic carbon.

However, the main limitation of gas fermentation, in general, and syngas fermentation, in particular, is the limited solubility of the gaseous phase, limiting its bioavailability. This, in turn, reduces the productivity of the process. One of the best ways to increase solubility is to increase the pressure inside vessels. Bioreactors, especially metal-made ones, can be pressurized, helping to overcome this limitation. An extra concern that some gases can present (e.g., H2) is their potential flammable/explosive characteristics. This issue can be worsened by the need of certain microorganisms for oxygen for their fundamental metabolism. Real-time measurements can help to monitor the concentration of the different reagents involved in the biological reactions. Using tight control measures, such as nitrogen flushing, and feedback loops, can help guarantee that the conditions inside the bioreactor are never close to unsafe values.

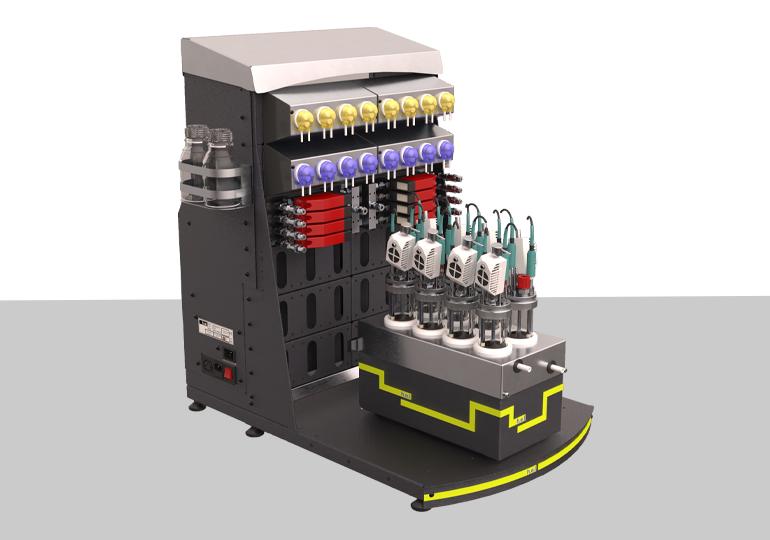

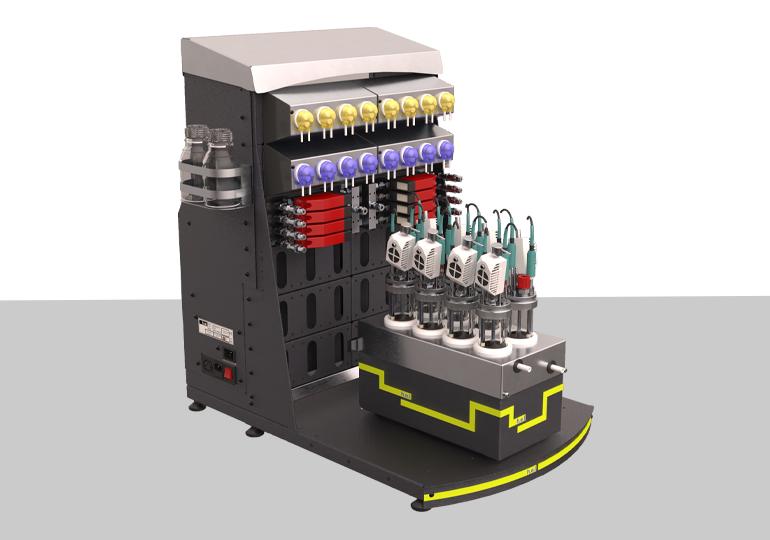

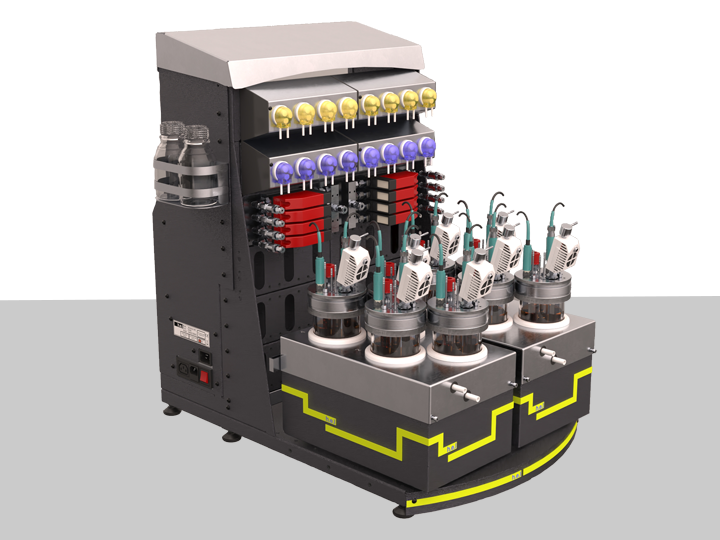

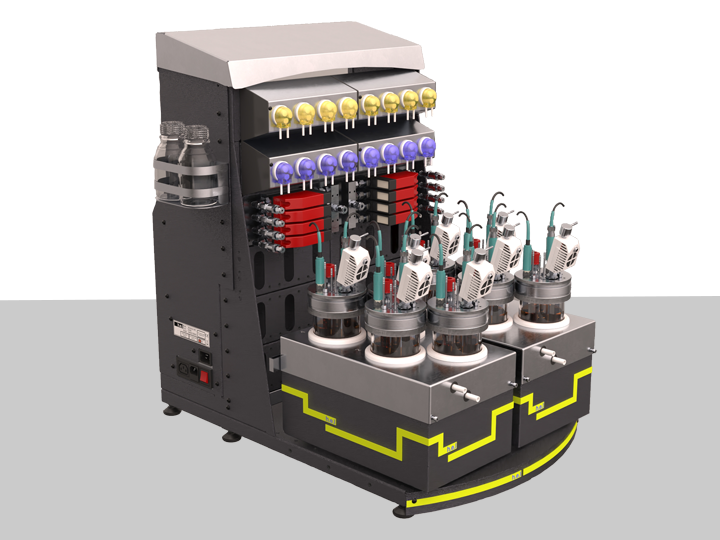

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a multi-bioreactor system designed for the optimization of aerobic f...

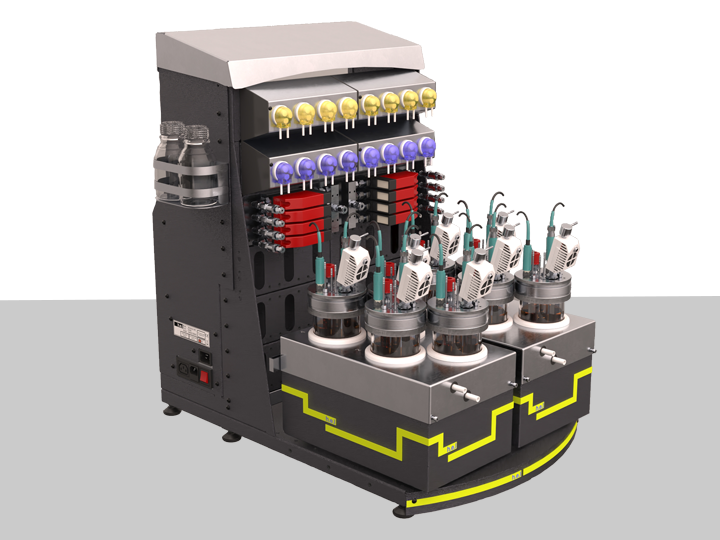

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...

How can the media feed be optimized?

Different strains have different medium requirements in terms of carbon and nitrogen sources, vitamins, and micro and micronutrients. However, different feeding strategies will also impact the growth and efficiency of cultures.

Batch feeding

This approach adds nutrients to the bioreactor in a single batch. It proves a controlled and defined nutrient environment for the screening process.

Fed-batch feeding

This type of feeding consists of continuous or intermittent feed addition throughout the cultivation process. Fed-batch feeding provides greater control over nutrient availability. Tuning the feed rate, nutrients, and compositions can result in significant growth, productivity, and product quality.

Continuous feeding

This approach consists of the continuous addition of feed of nutrients to the bioreaction at a constant rate throughout the process. This results in a controlled nutrient availability and growth rate, enhancing product performance.

Solutions

The BioXplorer is a powerful tool for screening processes. Its capabilities to control the different vessels (4 or 8, depending on the BioXplorer model) individually allow for evaluating different parameters, producing exceptionally accurate and detailed data. On the other hand, its integration with WinISO allows for the automatization of the process, reducing the risk of human error and the tight control of the conditions. This results in the generation of statistically robust data. Combining these capabilities, positions the BioXplorer as an invaluable tool for effective and efficient bioprocess screening.

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a multi-bioreactor system designed for the optimization of aerobic f...

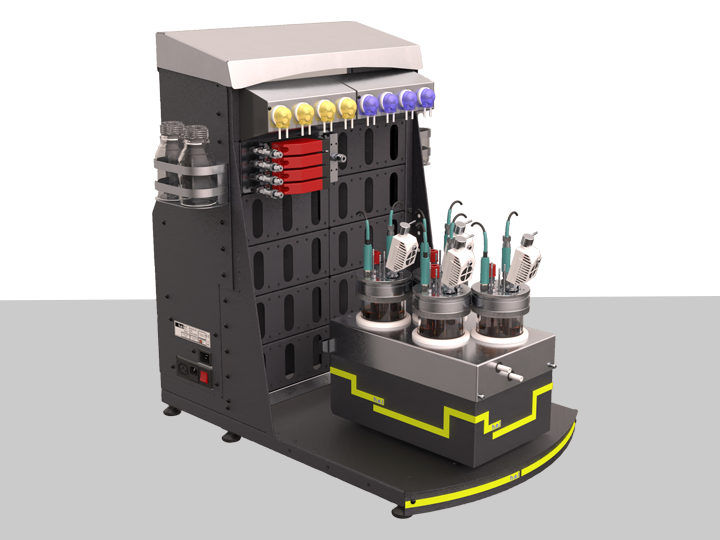

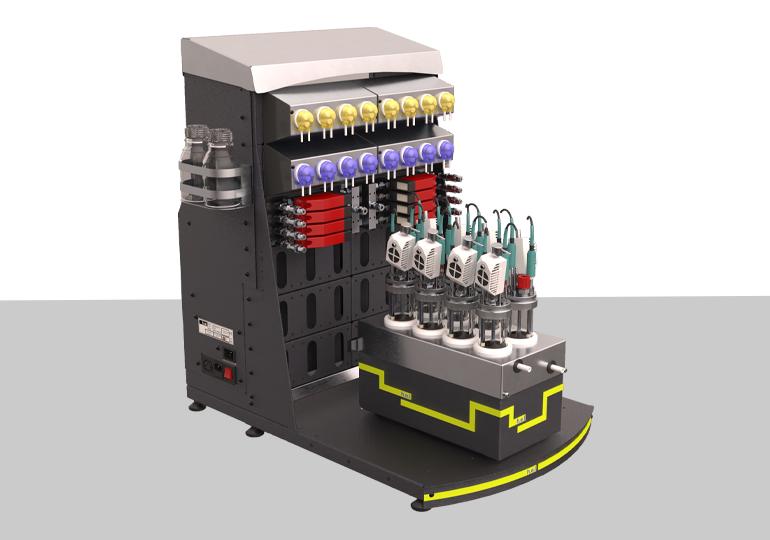

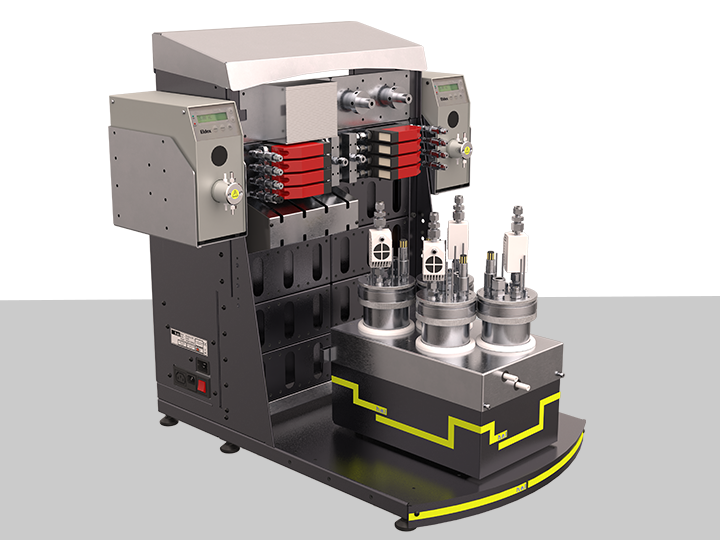

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...

How can the different processes be compared using bioreactors?

To improve bioprocesses, parallel experiments with different conditions, variants, and strategies are fundamental to finding the optimal conditions for cell growth, productivity, and/or product quality. This step is improved by the capacity of running several bioreactors at the same time, in which the different variables are modified to try to identify the right array of values. Additionally, bioreactors allow for the automatization of the process, increasing the statistical relevance of the results and decreasing the risks of human error.

Solutions

The BioXplorer is a powerful tool for screening processes. Its capabilities to control the different vessels (4 or 8, depending on the BioXplorer model) individually allow for evaluating different parameters, producing exceptionally accurate and detailed data. On the other hand, its integration with WinISO allows for the automatization of the process, reducing the risk of human error and the tight control of the conditions. This results in the generation of statistically robust data. Combining these capabilities, positions the BioXplorer as an invaluable tool for effective and efficient bioprocess screening.

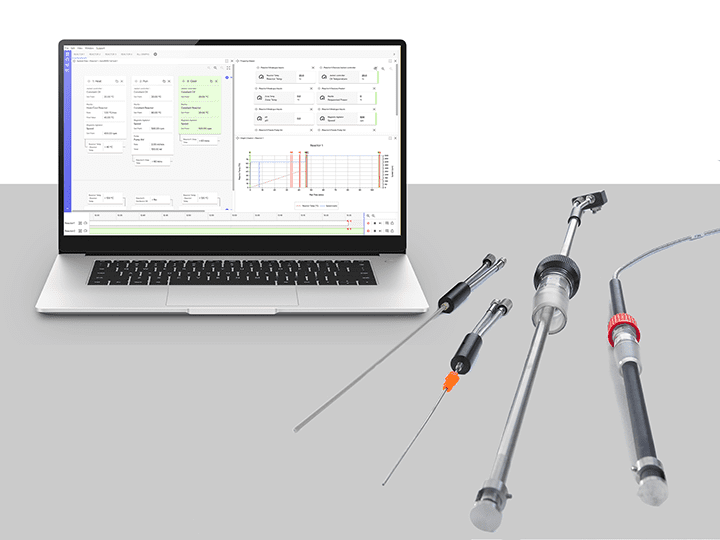

BioVIS | An Inline Cell Density Indicator Sensor

BioVIS is a probe for the inline monitoring of total cell growth and biomass within a bior...

BioXplorer 100 | bench-top, parallel 8 bioreactor platform

The BioXplorer 100 is a multi-bioreactor system designed for the optimization of aerobic f...

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

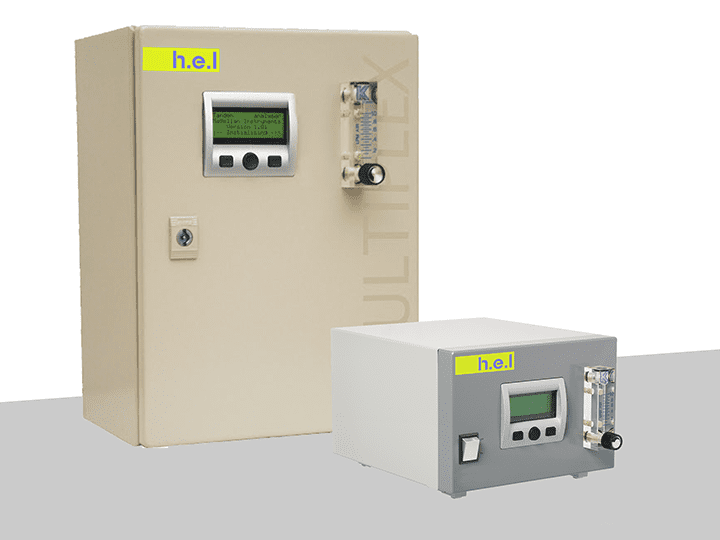

Tandem Off Gas Analyzers | Multi Line and Continuous Systems

The Tandem gas analyzer systems will give you real-time, on-line data that helps you under...

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...

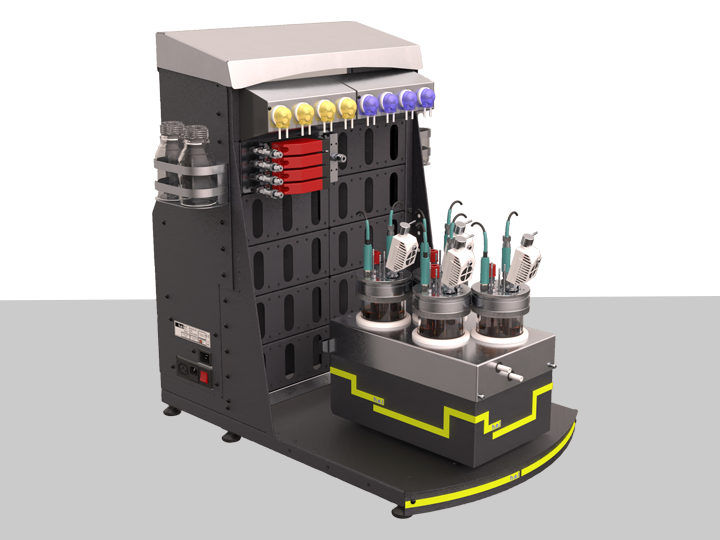

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery ...