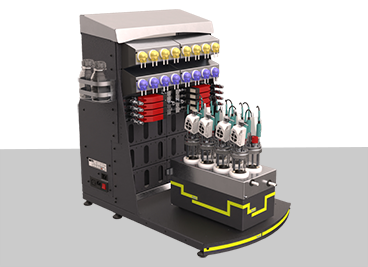

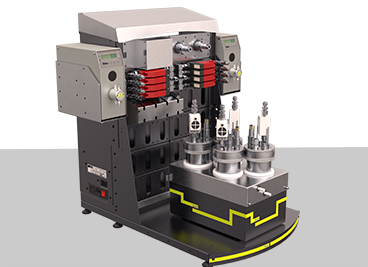

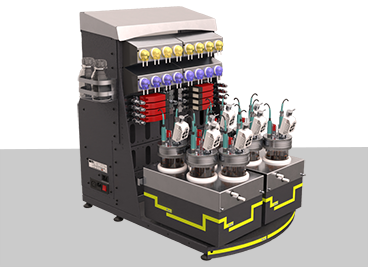

Bioreactor Systems

From 50 mL to 5 L, the H.E.L bioreactor systems offer automated, parallel experimentation. These systems can operate at high pressures, which makes them excellent for gas fermentation and bio-production research. Bioreactor solutions for small-scale process development and cell line/strain screening are available, and the reactors are flexible and adaptable for bacterial and cell-culture applications.

Our parallel bioreactor systems are excellent for research, screening, or optimization studies parallel bioreactor systems are excellent. You can more efficiently scale up your optimal culture conditions to pilot or production scale with the capacity to replicate conditions in much larger reactors. The multi-liter variants are designed to bridge that gap of process development and optimization. Our platform includes automatic feeding, pH, temperature, pressure, stirring, and gas mix control for cultures that must be kept in steady-state settings. Alternatively, each reactor can simultaneously evaluate a range of culture conditions to identify the sweet spot for your culture.