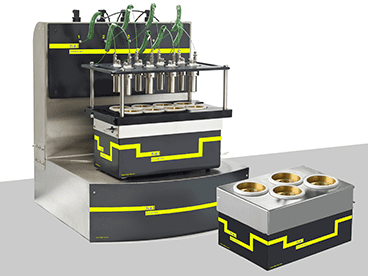

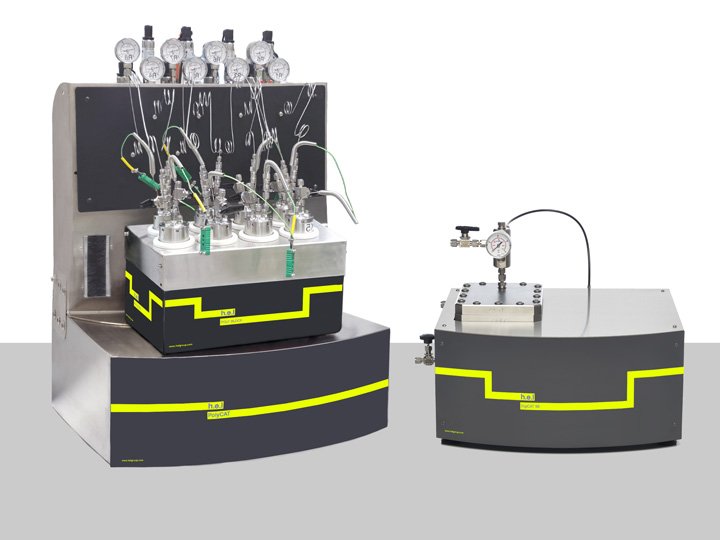

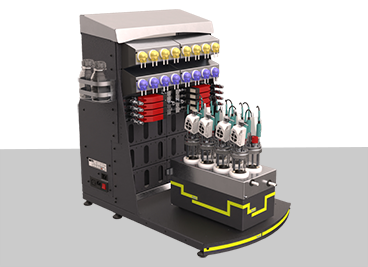

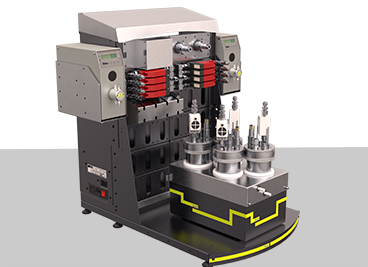

Parallel Reactor Systems

We offer a range of automated, benchtop, parallel reactor systems that support experiments between 20 ml to 500 ml. These systems can work across a broad temperature range; typical configurations from -40°C up to +200°C, but customized options can go beyond. We also specialize in offering high-pressure options perfect for when you need to work at 200 bar pressures safely.

From specialized applications such as crystallization studies, catalysis, hydrogenation, microbiological research, gas fermentation, and bio-production studies, we tailor the equipment to your specific research needs.

The parallel systems are ideal for research, screening, or optimization studies. With the ability to simulate conditions from much larger reactors, you can take your process conditions to pilot or production scale more effectively.

Our systems will also support complex multi-parameter experiments with automation, process control, safety monitoring, and data capture through the labCONSOL platform.